Find Circulating Cooling Water Water Treatment, Circulating Cooling Water Treatment, Cooling Water Treatment Equipment on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

New Products

| Min. Order: | 1 Set/Sets |

|---|

Product Description

Circulating cooling water refers to the exchange of heat through the heat exchanger or direct contact heat exchange method to exchange the heat of the medium and the cooling water through the cooling tower, which is recycled to save water resources. Under normal circumstances, the circulating water is neutral and weakly alkaline, and the pH value is controlled between 7-9.5; in the case of the circulating cooling water in direct contact with the medium that is acidic or alkaline (pH greater than 10.0), generally less.

The cooling of circulating water is the result of the three processes of evaporative heat dissipation, contact heat dissipation and radiation heat dissipation through the contact between water and air.

1. Evaporation and heat dissipation: Water forms large and small droplets or extremely thin water films in the cooling equipment, expands its contact area with air and prolongs the contact time to strengthen the evaporation of water, so that water vapor can take away the vaporization needed from the water. Heat thus cooling the water;

2. Contact heat dissipation: water is in contact with lower temperature air, and the heat in the hot water is transferred to the air due to the temperature difference, and the water temperature is reduced;

3. Radiation heat dissipation: The phenomenon that heat energy is transmitted in the form of electromagnetic waves without the effect of heat transfer medium.

The treatment of circulating cooling water can be summarized into the following four aspects:

1. Removal of suspended matter: By adding a side filter device, the flow rate of the side filter is generally 1%-5% of the circulating water volume, and the suspended matter is removed by filtration.

2. Control scaling;: softening and desalting or adding antiscalant.

3. Corrosion control: adding scale inhibitor to form a thin film on the metal surface to cover the metal, thereby isolating it from corrosive media and preventing metal corrosion.

4. Controlling microorganisms: adding biocides.

The cooling equipment is divided into open type and closed type, so the circulating cooling water system is also divided into two types: open type and closed type. The design and operation of open systems are more complicated.

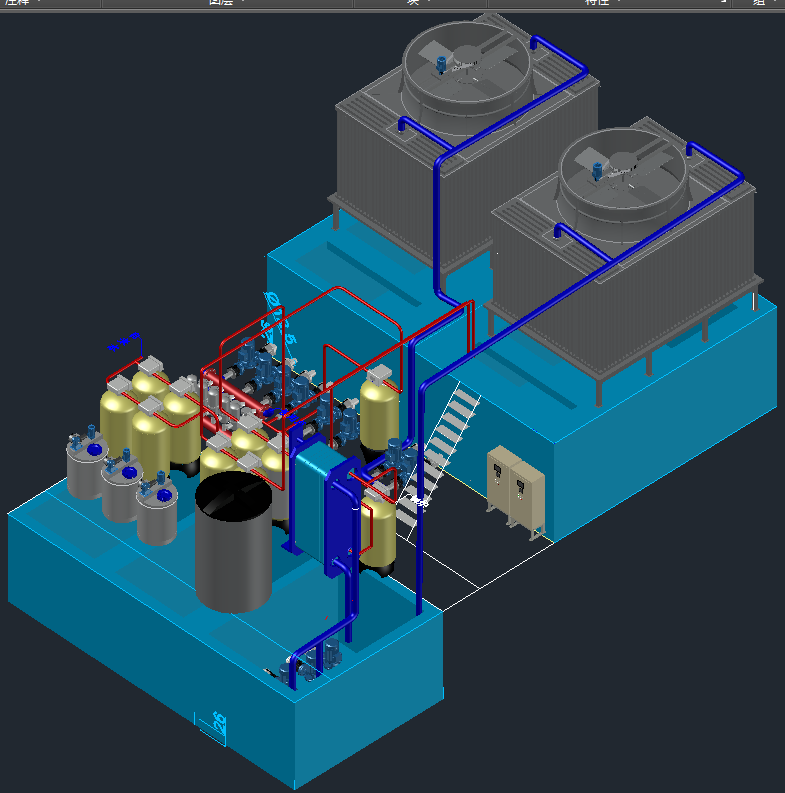

Open type: There are two types of cooling equipment: cooling pool and cooling tower, both of which mainly rely on water evaporation to reduce water temperature. Furthermore, cooling towers often use fans to promote evaporation, and cooling water is often blown away. Therefore, the open circulating cooling water system (Figure 1) must be supplied with fresh water. Due to evaporation, the circulating water is concentrated, and the concentration process will promote SALT scaling (see Sediment Control). The make-up water has a diluting effect, and its flow is often determined according to the concentration limit of the circulating water. Usually, the amount of supplemental water exceeds the loss of evaporation and wind, so some circulating water (called sewage) must be discharged to maintain the balance of water. Circulating cooling water system

In an open system, dust and microorganisms enter the circulating water due to the contact of the water flow with the atmosphere; in addition, the escape of carbon dioxide and the leakage of materials in the heat exchange equipment; also change the water quality of the circulating water. For this reason, circulating cooling water often needs treatment, including sediment control, corrosion control and microbial control. The determination of the treatment method is often related to the amount and quality of the make-up water, as well as the performance of the production equipment. When using multiple agents, avoid possible chemical reactions between the agents.

Closed: The closed circulating cooling water system adopts closed cooling equipment, the circulating water flows in the pipe, and the outside of the pipe is usually cooled by wind. Except for the material leakage of the heat exchange equipment, no other factors change the water quality of the circulating water. In order to prevent salt scale in the heat exchange equipment, sometimes the cooling water needs to be softened (see water softening). In order to prevent the heat exchange equipment from being corroded, corrosion inhibitors are often added; when using high-concentration, highly toxic corrosion inhibitors, pay attention to safety, and the cooling water discharged during maintenance should be properly disposed of.

Suzhou Weizhi Water Treatment Equipment Co., Ltd. was established in 2008. The company has more than ten years of water treatment technology. It is a professional water treatment equipment company in Suzhou. By the end of 2019, water treatment technology has successfully implemented more than 1500 projects at home and abroad, with equipment treatment capacity of more than 60000 tons / day, and has solved water problems for more than 1500 customers, Industries involved: environmental protection, chemical industry, machinery, medicine, electronics, food, community water and other equipment; The company's existing production equipment: wastewater treatment equipment, reclaimed water reuse equipment, ultra pure water equipment, pure water equipment, evaporation equipment, etc; R & D projects: treatment of waste leachate, seawater desalination, application and development of energy recovery device, remote data acquisition of sewage treatment equipment and guidance tips for on-site practical application. Patents: at present, the company has 3 invention patents, 12 practical patents and 13 software patents. In addition, the company provides customers with fast and high-quality services with complete production and manufacturing plants, perfect design, excellent construction quality and perfect after-sales service quality. With the successful practice of thousands of projects, the company has extremely rich experience in design, implementation and operation.

Product Categories : Circulating Cooling Water Equipment